Key Advantages:

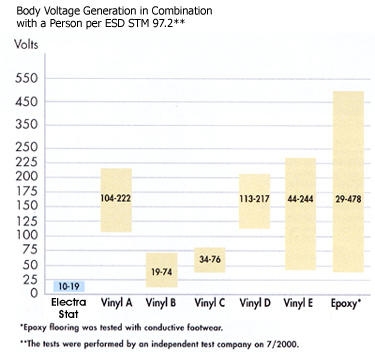

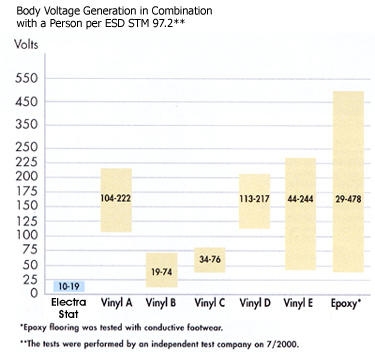

Body Voltage:

Impact on floor covering

The ability of ESD flooring to both inhibit

charges generation and dissipate any

accumulated charge with an acceptable

decay time are two totally different

properties that should always be considered

during evaluation and selection of ESD

flooring. A floor with low body voltage

generation properties minimizes the

charge created by movement of people

and equipment.

The ElectraStat Solution

ElectraStat ESD flooring minimizes any charge

accumulation. If you generate less charge,

you have to dissipate less charge. Less to

worry about!

Experimental Procedure and Results

- ESD STM 97.2 (Voltage Generation of

Flooring in Combination with a person)

Industry Standard Heel Straps with

I meg-ohm resistor, utilized for

evaluation.

- All materials (Flooring, Heel Straps)

were conditioned at 12% RH for 72

hours before test.

- Test completed in 12% RH condition.

- The maximum and minimum absolute values from each test is reported.

Compliance with ANSI/ESD S20.20-1999

This standard stresses the importance of

two test methods when evaluating ESD

Control Flooring:

Voltage Measurement on a Person -

ANSI/ESD S20.20 suggests that your floor

should not generate more than 100 volts

on a person's body. ElectraStat ESD Control

Rubber Flooring will not generate more

than 10 volts on a person's body. (In

conjunction with conductive footwear,

using ESD STM 97.2)

Resistance Measurement in Combination

with a Person -

This test method takes into

account the person and their footwear.

Test results show that noram static

dissipative rubber flooring performs as

well as conductive products, measuring

well below the ANSI/ESD S20.20

recommended limit of 35 meg-ohms to

ground (using ESD STM 97.1)

Outgassing:

An independent test company provided

the following outgassing values of different

floor coverings according to ASTM E-595.

The test method covers a screening

technique to determine the Volatile Content

of Materials (VCM) when exposed to a

vacuum environment.

Three parameters are measured: total

mass loss (TML), collected volatile

condensable materials (CVCM), and the

amount of water vapor regained (WVG).

The CVCM parameters are one of the best

indicators to evaluate the outgassing

properties of an ESD floor covering.

ElectraStat ESD flooring has extremely low

outgassing. This is due to the fact nora"

rubber flooring contains no volatile

plasticizers.

Additional benefits with using ElectroStat floor

covering with no plasticizers include:

- Dimensional Stability - nora" sheet/tile

rubber flooring is not prone to shrinking

due to its vinyl plasticizer-free composition.

- Better Chemical and Stain Resistance -

all ElectroStat rubber floors are free of PVC

and have extremely dense surfaces

which provides floors which are easy

and inexpensive to maintain.

|

Outgassing

comparison

according to

ASTM-E-595

(CVCM)

Independent Testing

Company, 1996/1998

Definition of CVCM:

Collected volatile

condensable material -

the quantity of outgassed

molter from o test specimen that condenses on a

collector maintained at a

specific constant

temperature for a specified

time. CVCM is expressed as

a percentage of the initial

specimen mass and is

calculated from the candensate mass determined

from the difference in mass

of the collector plate before

and after the test. |

Maintenance:

In many manufacturing areas, floor

maintenance may not be a top priority.

Maintenance has traditionally been linked

to aesthetics, not ESD prevention.

In addition, floor cleanings and ESD

waxing may interfere with the

manufacturing process and delays are

typically costly. A floor, that would

require as little maintenance as possible,

is preferable. The cost of maintenance

could be extremely high due to the

typically large square footage of most IC

manufacturing and assembly plants (i.e.

1,000,000+ sq ft).

The advantage of the non-porous surface,

of noram rubber floor coverings, combined

with "ElectraStat cleanguard'", the dirt repelling

feature of all norae rubber floor coverings,

permits easy and inexpensive cleaning.

The extremely hard wearing surface of

nora' floor coverings offers a whole series

of advantages in care and maintenance.

There is no need for coatings, therefore:

- No travel path formation

- No flaking and yellowing of a coating

Our ElectraStat Rubber ESD flooring

successfully maintains its appearance for

years even in heavy traffic areas with

round the clock operations.

|

| Navigation |

|

|

| Technical Documents |

|

|

|

|

| |

|

to find out.

Have a Question? Get a Quote Now!!

to find out.

Have a Question? Get a Quote Now!!